SuReTM Styrene: A sustainable process to recover Ultra High Purity Styrene from waste polystyrene via chemical recycling

Polystyrene (PS) chemical recycling, as opposed to mechanical recycling, is an emerging route to establish circularity in PS and qualify the recycled PS for stringent applications like food grade PS. To promote this circularity, the crude pyrolysis oil produced from the depolymerization section needs to undergo styrene purification to produce an ASTM qualified styrene monomer for downstream polymerization.

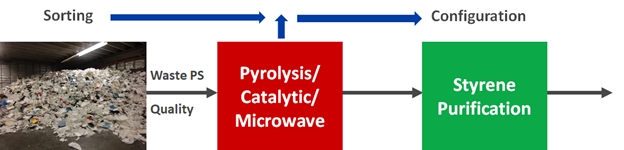

The value chain of polystyrene chemical recycling involves the following three main steps:

- Sorting,

- Depolymerization, and

- Styrene Purification.

There is a need to have a tailored styrene purification scheme because the crude pyrolysis oil, obtained from the depolymerization section, can contain impurities which either co-boil or close boil with styrene monomer and either cannot or are difficult to remove by conventional distillation resulting in failure of ASTM specification.

Examples of such impurities are o-xylene, phenyl acetylene, 1-nonene, oxygenates, sulfur, chlorinated, nitrogenated, close boilers like ethyl benzene, cumene, etc. These impurities can stem either from the waste PS feedstock wherein, despite usage of state of art sorting methods, unwanted plastics may still be present or depolymerization section wherein such impurities can be produced. Hence, there is a need to have a robust styrene purification solution which can accommodate removal of such impurities.

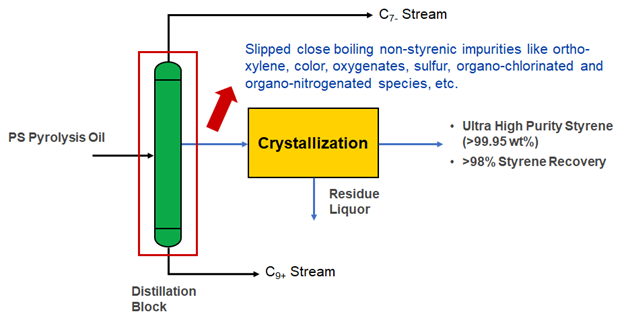

Sulzer Chemtech is pleased to present its SuRe™ styrene purification technology which overcomes the issues as stated earlier. It is a hybrid technology wherein distillation is coupled with crystallization at the back end. During the distillation process, an impure styrene stream purity is produced and fed into the crystallization section at the back end. The crystallization section offers the following key advantages:

- The bulk removal of the close boilers like ethyl benzene, cumene, etc., is done in the distillation section. However, the fine removal, wherein there is a disproportionate distillation energy requirement to meet ASTM levels, is accomplished via crystallization at a significantly less energy penalty. This is because melting energy is much less than boiling energy.

- All co-boilers like o-xylene, phenyl acetylene, etc. are removed to below ASTM acceptable limits. In addition, crystallization removes other impurities like oxygenates, sulfur, chlorinated, brominated, nitrogenated species, etc.

Melt crystallization is an apt process for the purification of styrene. A crystalline layer grows from melt on a cooled heat transfer surface. The driving force for the crystallization results from the net effect of temperature gradient across the solid and liquid phase. Under these conditions the crystal growth rate is 10 to 100 times faster than in suspension crystallization. Impurity-rich melt is drained from the layer by sweating and liquid styrene is recovered by melting the crystal layer. Centrifuges, or filters or wash columns are not used for solid/liquid separation. New developments allow optimizing the SuRe™ Styrene process for maximum purity and yield and overall plant economy.

Main features include:

- high yield;

- environmentally friendly, no use of solvents

- less operating personnel required

- flexibility when dealing with varying feedstock qualities

- short product change over times with no loss of throughput

- flexible adjustment of final product quality

- investment cost savings, due to optimized process integration

- energy cost savings, due to optimum combination of distillation and crystallization

- maintenance cost savings, due to use of proven equipment

Thus, the overall solution is not only CAPEX and OPEX attractive but is immune to feedstock impurities or upsets which can pose a concern if only conventional distillation is used as a solution. The key value propositions of SuRe™ styrene purification are:

- Variability in PS waste has no impact on styrene quality that is produced.

- Co-boiling impurities such as o-xylene, phenyl acetylene, 1-nonene, etc., don’t impact the final styrene quality. These impurities can come from waste or the depolymerization process. Further, the unit operation takes care of oxygenate removal too. Also, the cryogenic nature of the process avoids any polymerization issues with styrene.

- The styrene produced requires no blending. In case of a distillation only configuration, the recycled styrene produced will more than likely require blending with conventional styrene to dilute the presence of certain impurities which cannot be removed by distillation alone. Examples of such impurities have been cited in preceding sections. In case any of the co-boiling impurities turn out to be higher than designed then the blending approach will fail due to the requirement of large extra conventional styrene volumes. This has impact also on any future plans for scale up of recycled PS production by a client. In case of SuRe™ styrene process, due to usage of crystallization at back end, there is no requirement of blending since all these impurities are removed with ease.

- In principle, a client can produce a 100% recycled PS product with this technology as opposed to producing say a 10-20% recycled PS product via the blending approach. This will have appeal in case a premium for recycled PS develops in the future due to upcoming legislations in waste plastics. Market surveys done in the EU subcontinent indicate that the consumer has an inclination and is willing to pay for higher recycled content in plastics up to an extent of 10% premium in pricing.

- The highest-grade PS can be produced since the styrene monomer will meet the most stringent standards. >99.95 wt% styrene with all other impurities below ASTM levels can be achieved and offered as process guarantees.

- In case the PS recycling facility is being located adjacent to a downstream polymerization facility, then PS purges from the downstream polymerization section can also be co-fed along with the PS pyrolysis oil in the SuRe™ styrene process. The styrene can be recovered from the PS purge which is otherwise lost as fuel oil stream since the purge contains co-boiling impurities like o-xylene.

- Barring the distillation energy requirements, the dominant utility in the backend crystallization section is electricity. Considering the present emerging trend of decarbonization via electrification, the styrene produced from SuRe™ process will not only be recycled but also decarbonized if renewable electricity is available at the site. The distillation energy requirements are almost entirely met by the fuel gas production from the upstream pyrolysis process.