Integrating Capital Project Work into Maintenance Turnarounds

INTRODUCTION

Maintenance Turnarounds represent significant cost expenditures for any refinery or petrochemical plant. An overrun in time and money on a turnaround can significantly impact the bottom line, involving as it does, not just the cost of the turnaround itself, but also the lost production opportunity of the days shut down and not producing. Consequently, it is clear that anything which can be done to improve overall efficiency and predictability of turnaround outcomes is a major boon to operational efficiency.

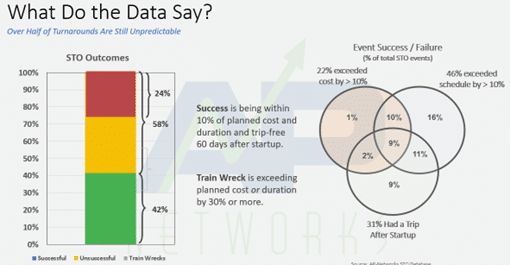

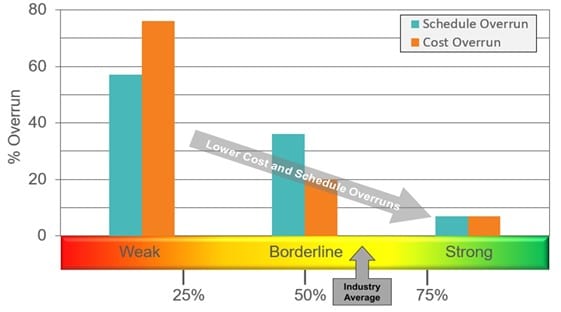

But unfortunately, AP-Networks database of more than 2,300 turnaround shows that more than half of turnaround fail to meet their cost, schedule and operability targets. And around half of those overrun their targets by more than 30% (Figure 1).

THE CHALLENGE OF PROJECT AND TURNAROUND INTEGRATION

Clearly, there is significant room for improving the efficiency and predictability of maintenance turnarounds. When turnaround teams are interviewed about their turnaround failures, a significant proportion place the blame on failure of project teams to properly integrate their field execution work with the main turnaround maintenance and inspection work. The lack of effective project-turnaround integration (i.e., creating a turnaround “event”) is a recognized pain point throughout all industries and a top reason why large events fail.

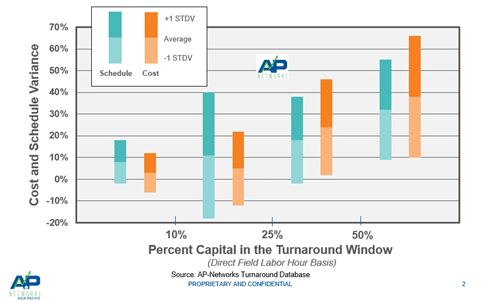

About eighty percent of brownfield or plant-based projects, regardless of their size, must execute part or all of their scope during a shutdown, turnaround, or outage. Since project work, as a proportion of turnaround event scope, is increasing, this makes finding a solution to the integration problem a topic of high importance for site operational efficiency. AP-Network research has shown that turnarounds are less predictable with increasing capital project (Figure 2).

To ensure the success of the project and turnarounds, integration early in the front-end is critical to achieving one combined, comprehensive, and cohesive plan with a fully aligned team to conduct flawless execution. The key challenge is the alignment of objectives. Projects and turnarounds each have their own success criteria—budgets, development schedules, and work processes. A misalignment of objectives leads to a dynamic tension between the two, contributing to communication gaps and a lack of awareness around the preparation status between these two functions.

So, what aspects of a project need to be integrated with the maintenance & inspection work; and how do we ensure that the integration is taking place?

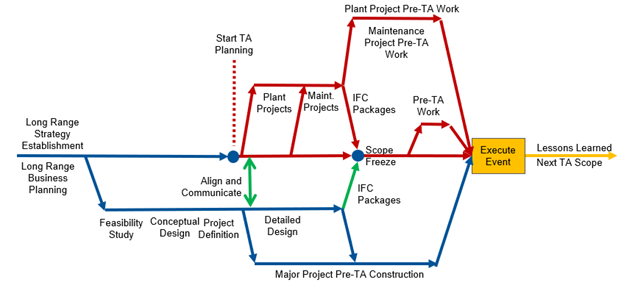

The first issue for both project and turnaround leadership to recognize is that integration issues must be resolved during the front-end definition period of the project. This means that if the project front end starts before the turnaround preparation period, then the onus for resolving integration issues shifts from the turnaround manager to the project manager and the site leadership. In other words, organizations need to map out and ensure there is an alignment of the main work process steps between turnaround and the various capital projects and plant-based projects to ensure key “touch points” are aligned with due dates. (Figure 3).

Figure 3 – Aligning of Main Work Process between Turnaround and Projects

As for the integration issues themselves, these include the need to align and integrate on topics such as overall objectives, contracting strategy, site supervision, scheduling, milestone planning and other topics.

In order to ensure that integration occurs there needs to be a three-pronged approach, based on:

- Procedures and processes.

- Verification and assurance.

- Roles and responsibilities.

Firstly the procedures and processes for development of the project front end definition need to include activities requiring the team to develop an integration plan. Tools such as AP-Networks’s iNTrack for plant-based projects and Turnarounds include such activities.

Secondly, timely adherence to those procedures needs to be verified, along with assurance that the deliverables produced are of sufficient quality. The AP-Networks system of “cold-eyes” Project Excellence and Assurance Consulting (“PEAC”) assurance reviews provides that verification and assurance.

Thirdly, site leadership and project leadership need to recognize that they, not merely the turnaround leader are also responsible for ensuring good integration into the turnaround event.

iNTRACK – BRIDGING THE DIVIDE WITH ARTIFICIAL INTELLIGENCE

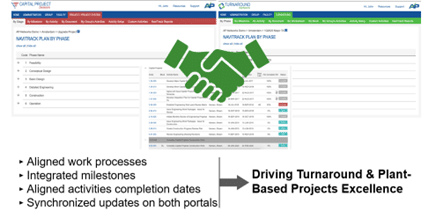

iNTrack is the first digital tool of its kind, creating a digital, dynamic handshake between project and turnarounds work processes. It allows for a free flow of information between projects and turnarounds, facilitating the creation of preparation and execution plans that seamlessly integrate project and turnaround scopes of work and execution plans.

Projects and turnarounds can naturally form a uniform event team when their processes are aligned and communicated. AP-Networks’ cloud-based NaviTrack work process deployment tool has long helped teams across the globe implement and deploy their work processes, providing real-time access to planning status, deliverables, job aids, and performance reporting. iNTrack allows the projects and turnarounds to dynamically connect their work processes within NaviTrack. Built-in artificial intelligence helps users easily identify the specific activities for integration. Flexible, real-time reporting options keep team members and stakeholders informed.

With iNTrack, users can quickly and easily view the status of integrated preparation activities that are on the critical path for both the projects and the turnaround. Examples include:

- Contracting Strategy

- Issuance of IFC deliverables

- Completion of project pre-fab activities

- Finalization of project-turnaround cost allocation structures

- Development of project QA/QC plan

- Execution Scheduling

- Placement of procurement orders

- Material Handling

PROJECT INTEGRATION PLAN

Finally, the Turnaround Event Manager needs to develop an integration plan for the Capital Projects and the Turnaround. The plan addresses how capital project work integrates into the turnaround planning. As discussed above, the capital projects have a work process with activities and milestones that do not necessarily align with the STO preparation process or timeline. The Turnaround Event Manager, in cooperation with the Projects Manager, should review key capital project activities and milestones and ensure that they are feasible. The project plan and timeline must be reviewed for any gaps with the turnaround management process. Integration is also needed with joint/separate contracting to cover needed contractor resources and to ensure safe execution and feasibility. The integration plan shall be endorsed by the Steering Team to confirm agreement.

By the act of developing a detailed integration plan, which will have a positive impact on the integration of capital projects and turnarounds (measured by AP-Networks proprietary tool Project Integration Index), AP-Networks has quantitatively demonstrated that there is measurable improvement in turnaround event average performance (Figure 5).

About the Author

Daniel Phan is a Regional Manager with Asset Performance Networks Asia Pacific Pte Ltd in Singapore. He has more than 20 years of experience in plant STO and project management consultancy in the oil & gas, petrochemical, maritime industries.

AP-Networks is the trusted leader for improving asset and operational performance in petroleum, chemical, mining, agricultural and other manufacturing companies worldwide. AP-Networks works with the client’s most critical assets—their people, processes, and production facilities—in order to help them achieve safe, competitive, predictable outcomes on their high-risk events—namely capital projects and STO.

Contact: dphan@ap-networks.com