Reforming Catalyst Testing

By: Tiago Vilela; Nicolas Popoff; Mark Moser

Catalytic reforming is an important process in the petroleum refining industry. It is used to produce high-octane reformate for gasoline blending and high-value aromatics. The process objective is to convert petroleum naphtha fractions to high-octane aromatic hydrocarbons as selectively as possible. Reforming also serves two other main purposes in a refinery: it is the main hydrogen producer for use within a refinery or outside it; it also provides feedstock (predominantly benzene, toluene, and xylene) for the subsequent downstream petrochemical production processes (JH, 1981).

Naphtha semi-regen (SR) fixed-bed reforming units are operated at relatively high pressure to mitigate coke formation. As coke deposition increases, reactor temperatures are raised to achieve the target octane. The SR reforming catalysts consist of noble metals impregnated on an alumina base, with a cylindrical or spherical shape. Bi-metallic catalysts composed of platinum (Pt) and rhenium (Re) are the most common type found in a fixed-bed unit.

The economic impact of changes in yield with a SR reformer can be significant. Assuming a 3000 t/d unit, a shift from C1-4 to C5+ of about 0.5% will result in a ΔGRM (Gross Refinery Margin) of 0.8 M€/a (3000×0.005x350x150€/a=0.8 M€/a). In the case that a refinery is hydrogen (H2) constrained, (e.g. the HCU is throughput constrained due to a lack of H2) this value could be significantly higher. Assume 10% higher H2 make that is roughly 8 t/d of H2. This could enable processing some 265 tones more of VGO feedstock (at 3% H2 consumption), which would represent an increased value of circa 9 M€/a.

Avantium provides independent comparative catalyst testing services to refineries to support the catalyst selection process with actual key performance data. For this, we utilize a proven testing methodology and a best-in-class, high-throughput 16-parallel reactors micro-pilot plant (Flowrence® technology). The resulting data quality (precision, accuracy and reproducibility) is continuously validated by the reforming catalyst vendors.

High data quality in these comparative tests means that the test results are reproducible and thus reliable for refineries to select the best performing catalyst for their operating conditions and feedstock. It is important to observe a catalyst performance in the commercial unit consistent with the performance obtained in the pilot plant. This confirmation obviously increases the level of confidence in the test results. In this article, we present a comparison of the key performance indicators C5+ yield and H2 of a commercial SR reformer with the Avantium micro-pilot plant test results for the selected catalyst.

The micro-pilot plant test

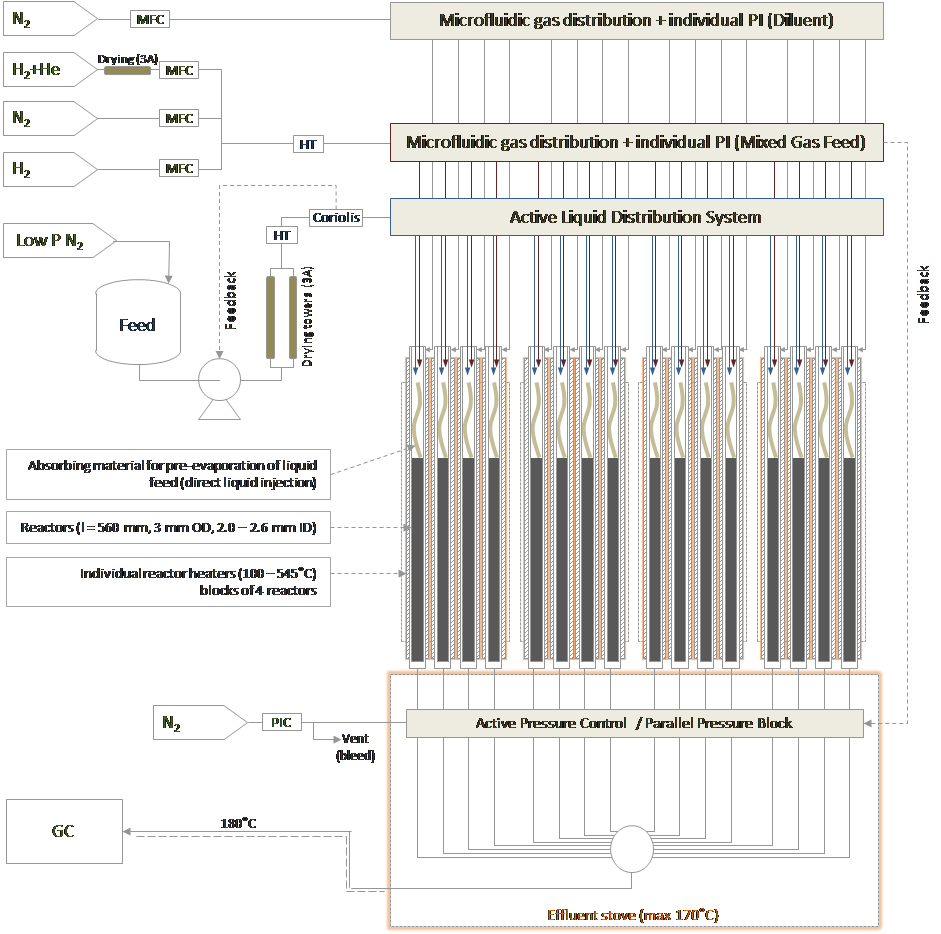

The comparative test included four naphtha SR reforming catalysts from different vendors, including the incumbent for benchmarking purposes. The pilot plant test was performed in a fixed-bed 16-parallel reactors high-throughput Flowrence® system (see Figure 1).

Figure 1: Flowrence® 16-parallel reactors high-throughput system

The performance of the catalysts (temperature required, C5+ yield and H2 production) is evaluated at fixed product severity (constant octane or Research Octane Number, RON). The iso-RON operation is achieved by using an automated feedback loop between the GC analysis of the effluent and the reactor’s temperature, which is thus continuously adjusted.

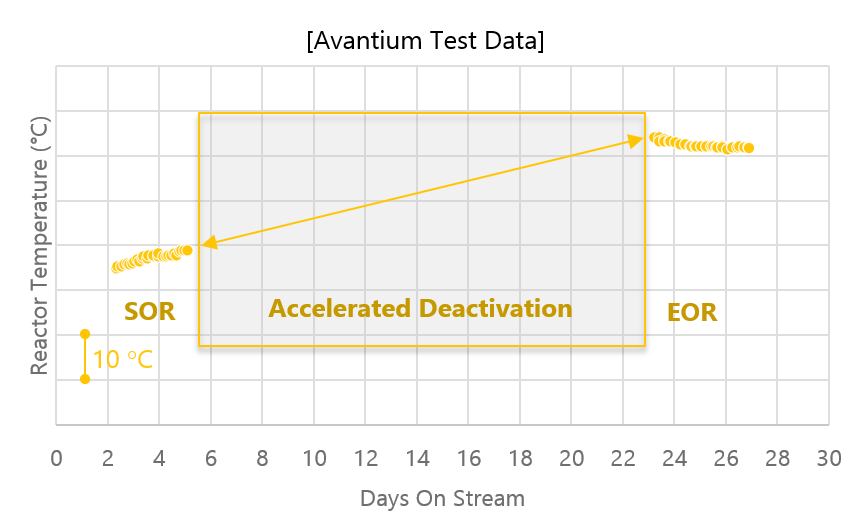

In order to simulate the commercial operation of the SR reforming unit we need to perform an accelerated deactivation protocol. It is necessary to increase the test severity i.e. accelerated deactivation to enable performing such tests in a reasonable timeframe; it would not be economically feasible otherwise. After a short break-in period, the catalysts are tested at iso-RON (target octane level) and plant operating conditions – Start-Of-Run (SOR), followed by an iso-RON accelerated deactivation (increased severity) and then back to plant operating conditions iso-RON (target octane level) – End-Of-Run (EOR).

In this article, we only present the micro-pilot plant test results from the catalyst selected by the refinery. We do not present the results from the other catalysts tested nor we disclose the refinery name due to the competitive nature of the catalyst selection process and to respect the confidentially agreements with the catalyst suppliers.

Figure 2 shows the reactor temperature profile with time-on-stream.

The EOR data set in Figure 2 shows approximately 25°C deactivation for the catalyst between the 5th day on stream and the 24th day on stream.

With the continuous analysis of the product effluent, these tests also provide refineries with a complete hydrocarbon breakdown for every point in time. The baseline separation of ethyl-benzene and all xylenes isomers, or the breakdown of the C1 to C6 products for example, are crucial for economic and integration studies.

Thanks to the availability of multiple reactors in the micro-pilot plant, each catalyst system was tested in triplicate reactors, in order to provide repeatability and confidence intervals on the results. This greatly increases the reliability of the test results.

Further than paper estimates, the possibility to simultaneously compare catalysts under various plant conditions and with specific feed properties (e.g. amount of coke precursors, presence of contaminants such as sulfur, etc.) is thus critical to determine the right catalyst.

Comparison with refinery commercial data

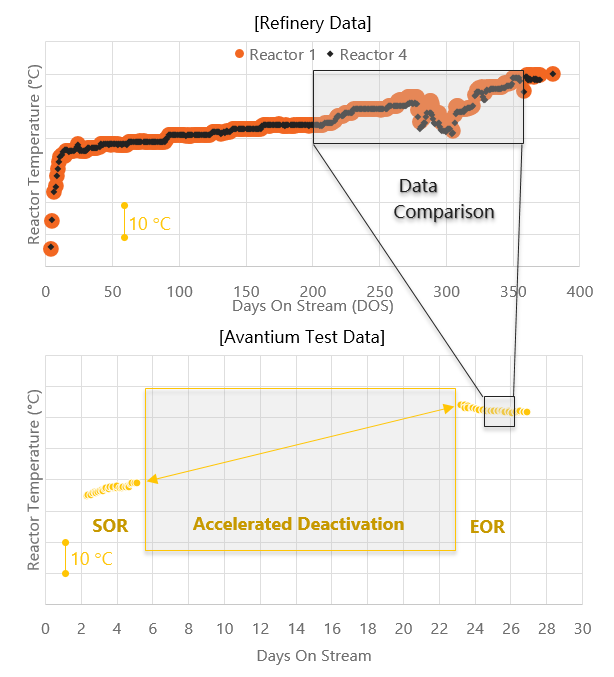

In order to compare the commercial operation data with the accelerated deactivation micro-pilot plant test results, we need to look into the actual reactor temperature data and make the comparison at similar Δ -WABT.

C5+ Yield

In order to compare the Avantium Test Data with the Refinery Data, we need to look at operating windows with similar catalyst deactivation, approximately 25°C deactivation. For this, we use the EOR Avantium Test Data between day 24 and day 26 [Days On Stream].

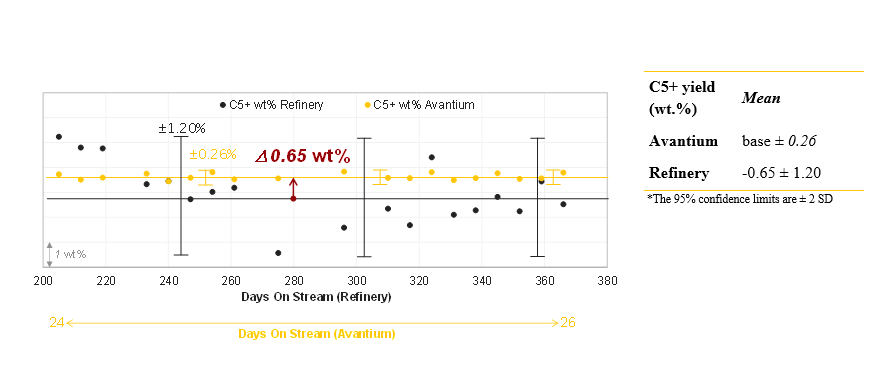

Figure 4 presents the comparison between the C5+ yield (wt.%) obtained in the micro-pilot plant (Avantium Test Data) and the C5+ yield (wt.%) obtained in the commercial SR reformer (Refinery Data) – EOR after 25 C Deactivation for both with 95% error bars.

As we can see, the difference between the average C5+ Yield obtain in the Avantium test data and Refinery commercial data is very consistent with a delta of 0.65 wt.%. We can also observe that the test data produced in the micro-pilot plant is more stable i.e. small standard variation than the commercial data.

H2 Production

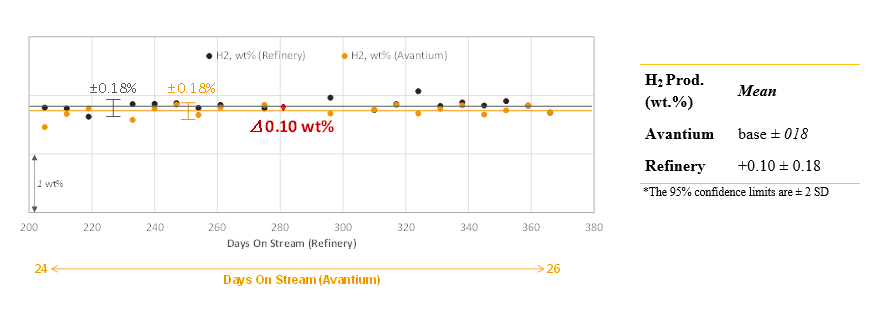

As a main H2 producer in the refinery, the higher H2 production the better. At the Avantium micro-pilot plant, we can measure real-time the amount of H2 produced during the test. Similar to the C5+ Yield, we also use the EOR Avantium Test Data between day 24 and day 26 [Days On Stream] to compare the Refinery Data and Avantium H2 wt.% data, both after 25° C deactivation (Figure 5).

The difference between the average H2 Production Avantium test data and the Refinery commercial data is extremely small, which is impressive for such small wt.% of H2 Production. Here the difference is just 0.10 wt.% with very stable data for both the test and the commercial data.

Conclusions

- The test results obtained in the Avantium micro-pilot plant are very consistent with those of the commercial SR unit operation for the key catalyst performance indicators, C5+ Yield and H2 Production.

- The Avantium Refinery Catalyst Testing services provides a reliable process (testing approach and micro-pilot plant) for comparing commercial Naphtha Reforming catalysts to enable refineries to test multiple options for their unit operating [relevant] conditions.

- The Avantium micro-pilot plant with 16-parallel reactors (Flowrence® high-throughput technology) and the methods applied, produce very high data quality (precision, accuracy and reproducibility) – extremely important for comparative testing of commercial catalysts.