Putting the catalysts to the test: the importance of catalyst testing for increased profitability

When catalyst loading represents an investment of up to US$ 20MM, making the right catalyst choice can be critical for business success. But operators lack the data, and the transparency, to make the best decisions.

Things are changing. Parallel testing and small-scale reactors are making big impact, and equipping refinery leaders with the resources – and the confidence – to make fact-based catalyst evaluations.

Tiago Villela, Director of Refinery Catalyst Testing, gives Avantium’s inside scoop on the challenges of choosing the right catalyst, the importance of catalyst testing for increased profitability, and why small-scale reactors are the next big thing.

Challenges in making catalyst choices

Refineries change out catalysts periodically, reloading with either fresh or regenerated used catalysts. For each change out or loading, there remains one constant, critical question: which catalyst or catalyst combination is most appropriate for the next cycle of the unit?

Choosing the right catalyst for your refinery infrastructure is a key factor that can have a major impact on the yields, energy usage, and ultimately the profitability of your refinery. A catalyst loading can represent $10-$20MM, making rigorous catalyst evaluation a valuable investment.

In short, a smart choice can set you up for success. But as the refining catalyst market experiences strong growth – and a predicted surge to US$ 4.7 billion within the next five years – making the choice in an increasingly competitive market can be challenging. Refineries – and their business leaders – still underestimate the impact of catalyst selection. Choices often are based on incorrect assumptions, few catalyst options are considered, and decisions are made without appropriate supporting test results.

With an estimated 50% of catalyst selections based on vendor forecasts only, there is a need for greater transparency, and clearer information to help operators make informed decisions [see also PTQ Jul-2019 Refinery Catalyst Testing].

Shift to small-scale reactors

In recent years, comparative catalyst testing in pilot plants has become the best practice for evaluating catalyst performance and the profit impact of process options. While previously, the performance of heterogeneous catalysts was evaluated using large reactor systems that typically vary between 20 to 300 ml, now smaller-scale reactors have entered the mainstream.

These smaller parallel reactors are not only a more compact, cost-efficient pilot plants. They are also usually more ideal in terms of heat flow and hydrodynamics compared to larger reactors and therefore provide data that is intrinsically easier to translate to a larger (industrial) operating scale. Downsizing your catalyst testing reactor also reduce the amount of feed required avoiding the typical issues associated with obtaining large quantities like handling, shipping and storage. Smaller volumes result in a lower level of energy consumption towards sustainability goals.

Making small-scale reactors big business

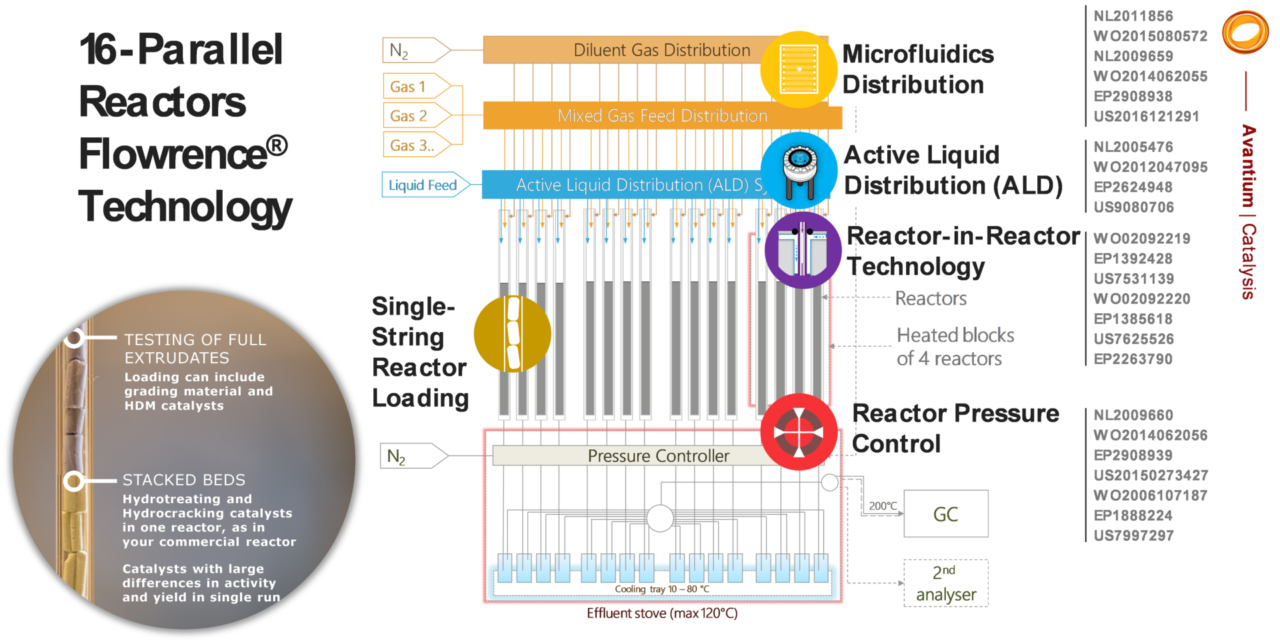

Avantium have grown small-scale catalytic testing to the next level. Below a schematic overview of the 16-parallel fixed-bed 16-reactors micro-pilot plant designed by Avantium (Flowrence® technology) in order to enhance catalyst selection for refinery applications.

This micro-pilot plant technology makes it possible to test up to 16 options simultaneously at no extra cost and with no increase in testing time.

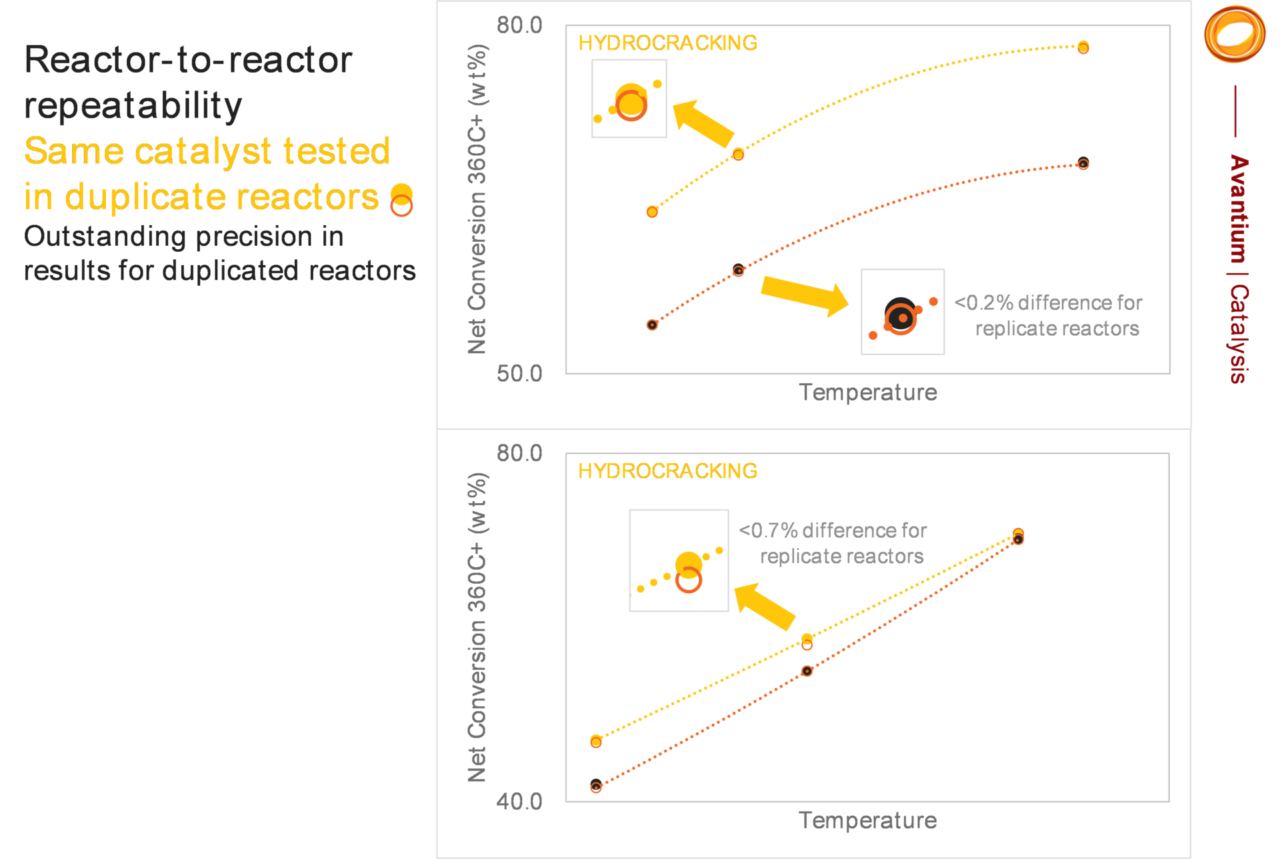

With this enhanced pool of data, business leaders have the opportunity for a more thorough evaluation, a fact-based decision, and a greater opportunity to increase refining margins. But like a well-planned juggling act, it should be executed with skill. When performing parallel testing of multiple commercial catalysts is important to have a system with excellent reactor-to-reactor repeatability and run-to-run reproducibility. This will ensure that the relative differences in catalyst performance are meaningful and reliable for refineries to confidently select the best catalyst for their unit.

Building confidence in your catalyst selection, and your business

Catalyst choice has a huge impact on both daily operations and long-term planning. And for some refinery units such as hydrocrackers this decision will have a major effect on the economics of the refinery. Parallel testing can take the pressure off business decision makers, equipping them with the best resources and information to make the right catalyst choice for their business.

16-parallel reactors allows for replication, for determination of statistical significance of results obtained and for simply evaluating more catalyst options at the same time (side-by-side). In addition, comparative testing should include the incumbent catalyst for relative comparison, which offers an increased level of confidence in the test results. This significantly increase the level of confidence in the pilot plant technology.

This sort of testing requires time, resources, and commitment from both those “on the ground”, and those at the top level of management. But the results are an increased level of confidence in your test results. And an increased level of confidence in your business decisions.

Read more:

- Aramco to Acquire 50% Stake in Air Products Qudra’s Blue Hydrogen Industrial Gases Company

- SK Innovation and SK E&S Announce Merger, Forming Asia-Pacific’s Largest Private Energy Company With Assets of KRW 100 Trillion

- Indorama Ventures Secures $200 Million Loan From IFC to Drive Sustainability Program

- Aramco’s Strategic Gas Expansion Progresses With $25bn Contract Awards

- GC CEO Narongsak Jivakanun Reveals Vision to Continue 3 Steps Plus Strategy and Drive Map Ta Phut to Become Southeast Asia Hub