How to leverage digitalization for sustainable manufacturing

In partnership with:

Sustainability is a broad topic and has been described as being made up of three pillars: the economy, the society, and the environment. These pillars are also casually referred to as the 3P’s – Profit, People and Planet. They are actively being integrated into investment analysis of portfolios and company operations, to screen potential investments and are further termed the ESG (Environmental, Social and Governance) factors.

Sustainability can be seen as a measure of the capability of the process(es) by which something is kept at a certain level.

Over the years, sustainability has become a necessity for enterprise growth – to improve processes, and add value.

Sustainable Practices in Process Manufacturing

“With changing market sentiments, sustainability is quickly becoming accepted as a key business parameter along with traditional metrics” says Dr Pratap Nair, CEO at Ingenero. “Operators are realizing substantial financial and environmental benefits from sustainable business practices”.

In recent years, there has been a growing concern over the depletion of non-renewable natural resources due to overexploitation, energy use and emissions in manufacturing operations, linear consumption of products, direction of investments, and lifestyle choices.

While climate change is a subset of the broader Sustainability area, for process manufacturers, sustainability has often been linked to climate change. Industrial processes definitely increase the level of CO2 in the atmosphere and it is estimated that this will cause trillions of dollars of damage each year. The Decarbonization initiative (a lower carbon future) is a means to achieve the climate change challenge.

“Today, sustainability is a key differentiator and a strategic business imperative that helps drive performance and top-line growth” states Dr Nair. “As long as a solution is found that causes little or no harm to the natural world, while allowing for a continued quality of life by today’s societal standards – this balance can be considered sustainable.”

Extensive sustainability programs to improve efficiency/energy have helped companies optimize resource consumption and accelerate growth through innovative products and services, all whilst driving environmental competences and brand value.

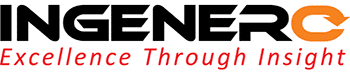

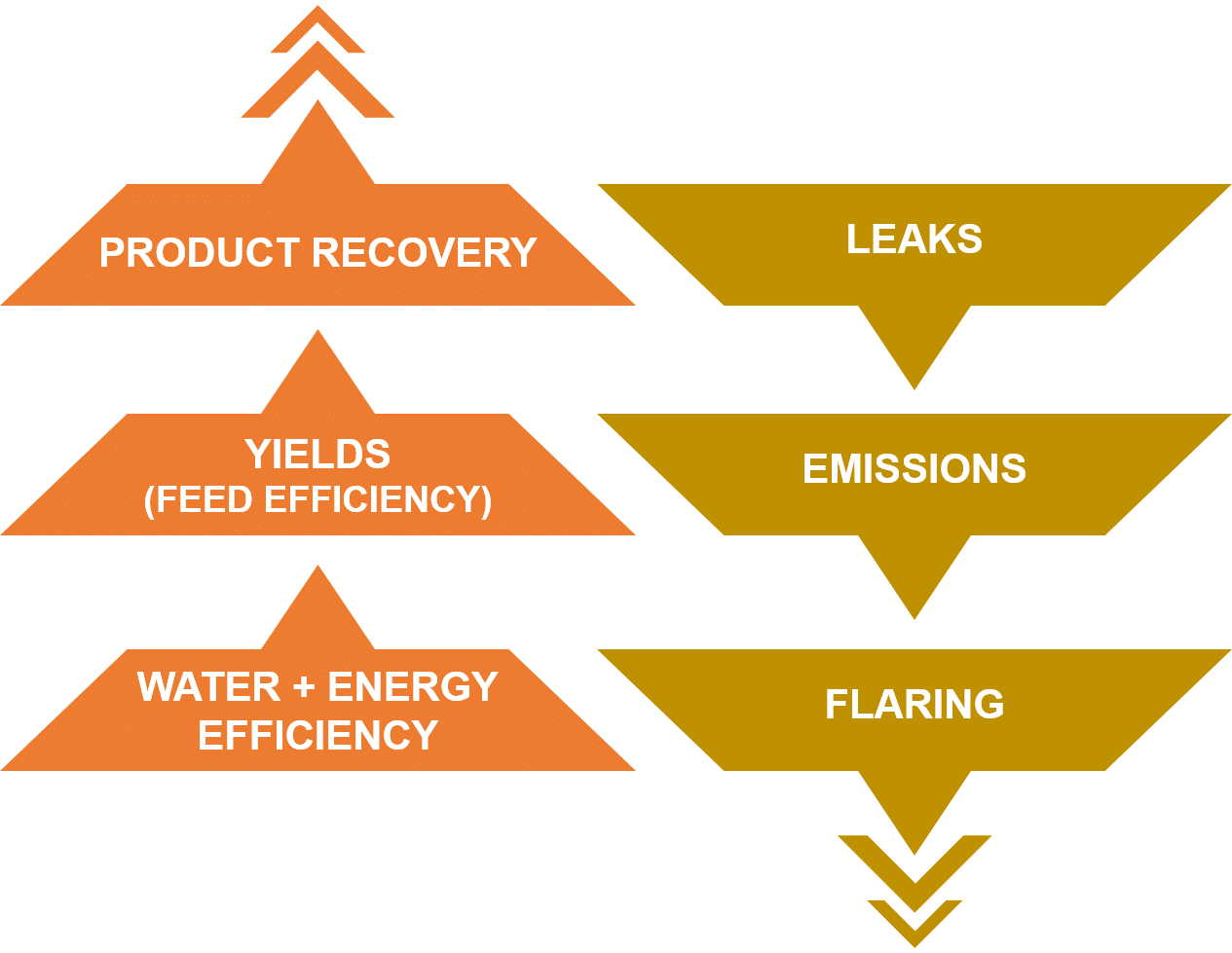

Sustainable manufacturing through efficiency initiatives, water initiatives, and physical waste initiatives can lead to immense savings and can be achieved through the following:

Digital Technologies – the way forward for Sustainable business

Sustainability and digital transformation are more than just industry buzzwords – they can be effectively implemented with cogent guidelines and seamlessly integrated into business operations achieving both goals together – Sustainability and Digital Transformation.

How can Process Manufacturers improve sustainable business practices with the help of digital solutions?

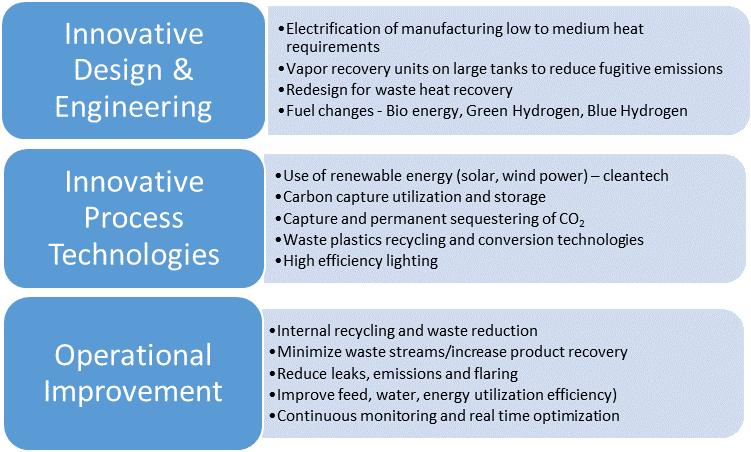

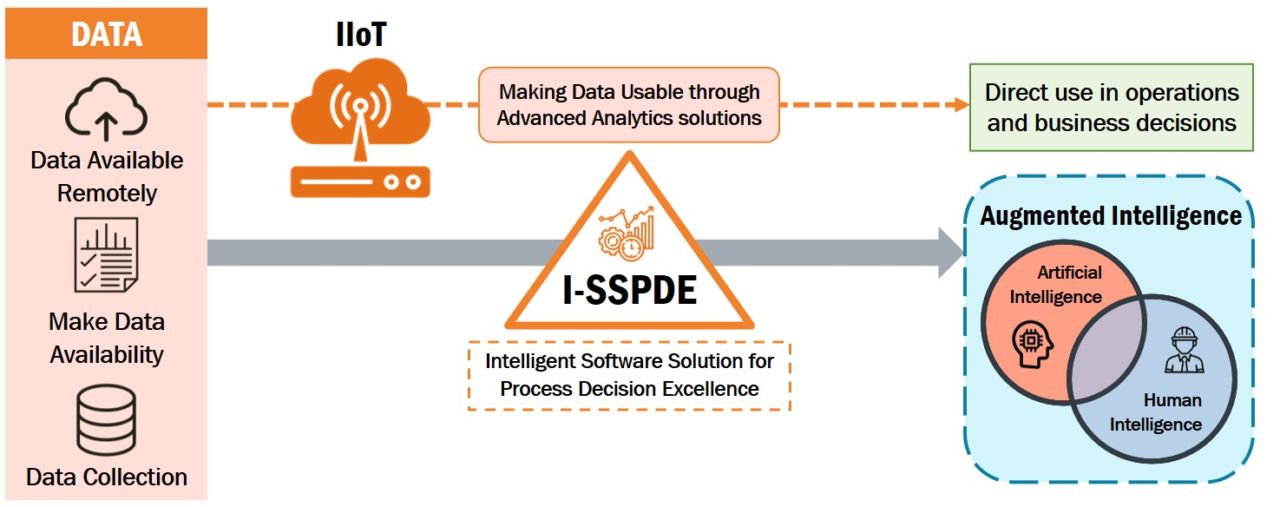

“Effective use of digital solutions utilizes digital technologies to convert data to Augmented Intelligence that brings operators closer to real-time information access when making decisions.” says Nair “This facilitates achieving sustainability in existing manufacturing units, while not losing sight of traditional business values”.

To effectively obtain Augmented Intelligence, operators will need a hybrid approach:

- Using the best available tools and technology to enhance human intelligence and;

- Allow creation of actionable intelligence.

One such example is the “Digital Twin” – which aims to provide decision makers with the information required to form intelligent solutions, by identifying the most effective and efficient ways through operational and/or design changes, in which they can dramatically reduce the use of energy and improve productivity, lowering carbon footprint.

Augmented Intelligence improves operational performance by providing:

- Faster Identification – More agile identification of process and/or equipment anomalies, leaks, etc.

- Faster Action – Lower losses of product and energy

- Reduced gap between plan and actual production from faster identification and response cycles

- Better and closer to real time ESG data reporting against benchmarks

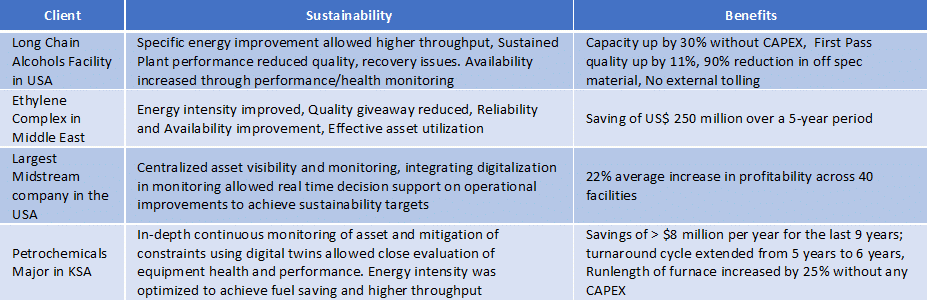

Case Examples –

Ingenero’s sustainable manufacturing support

Ingenero’s Sustainability Program, I-SSPDE, integrates edge computing with advanced analytics utilizing the full potential of Industrial Internet of Things (IIoT). By combining latest smart technologies and tools, I-SSPDE acts as a force multiplier and allows manufacturers to advance their energy management, safety modeling and automation processes.

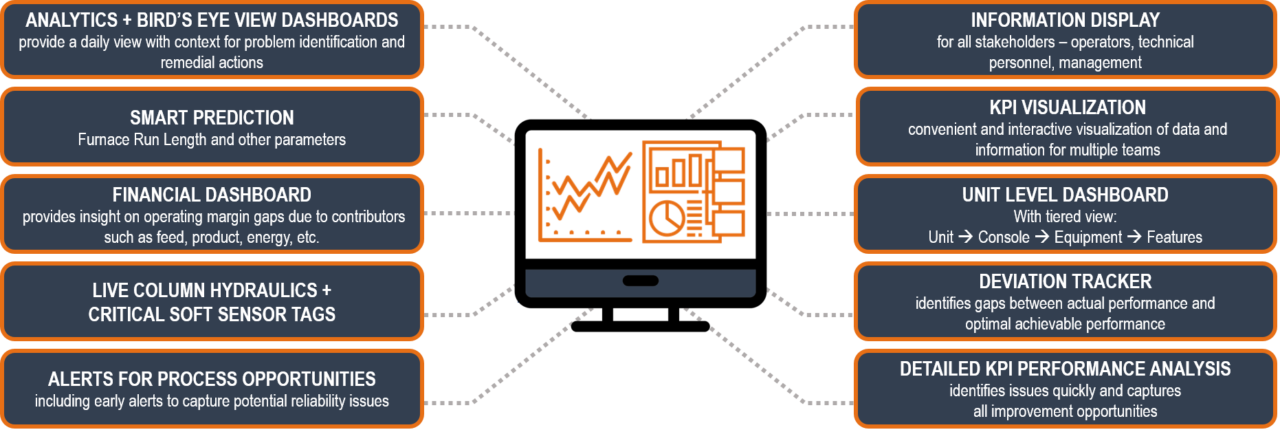

KPIs are tracked to provide both an intrinsic and extrinsic view of the process/equipment. This is encapsulated in a dashboard built by bringing together three separate industry standard views into one screen.

The dashboard provides:

- An Operational Outlook – which interprets large amounts of information, and provides continuous real time data to operators in a single, clear visual.

- An Analytical Outlook – which allows for further investigation into the data received through KPIs, enables users to investigate any anomalies in the data and uncover its root cause.

- A Strategic Outlook – which allows users to receive simulated solutions for any problems that the system identifies, thus highlighting any opportunity to optimize.

Benefits & Features of I-SSPDE

In conclusion, sustainability and profitability are not mutually exclusive. Operators are gradually understanding that this does not always translate to smaller profit margins. The industry might even have to go through some growing pains in the form of increasingly regulated and stricter frameworks in the coming years for the public good. Fortunately, by initiating the process to construct an integrated and digitized infrastructure, enterprises can rise up to the expectations of achieving environmental and operational sustainability while remaining profitable. By introducing sustainable policies and processes with the help of digitalization strategies, greater proficiencies can be seized and operators along with their companies can position themselves to experience smarter long-term benefits.

Ingenero strives to be the world’s leading process analytics and technical consulting company. Ingenero delivers engineering expertise and digital transformation solutions that enable increased production, sustainability, efficiency, safety and reliability. Ingenero makes its oil and gas, refining, mid-stream gas processing, petrochemical and specialty chemical industries clients safer, more effective, and sustainable through its engineering and technology services and solutions.

For more information, visit our website.

Read more:

- HyIS-one Selects Emerson as Automation Partner for Korea’s Largest Hydrogen Refueling Station for Commercial Vehicles

- Decarbonize FCCU Catalytically

- How Natural Gas Accelerates the Path to Hydrogen

- A guide to industrial AI and digital transformation

- Case Study: Material transition to aerogel insulation leads to energy efficiency and improved thermal management