Wolters Kluwer Enablon Dynamic Risk Visualization: A new vision for connecting Process Safety and Operations

The next step in bringing process safety management to the front line

As technology improves and becomes more easily available, organizations across oil, gas, and chemicals industries are embracing the digital future. Digital transformation is changing the way companies operate, helping to increase production efficiency, improve risk understanding, and streamline processes.

However, connecting corporate Process Safety Management initiatives to day-to-day on-site Operations is a continuing challenge. With a potential disconnect between Risk Assessment theory and actually executing complex work on site, PSM and Operations staff sometimes feel like they’re not speaking the same language.

This leads to a gap between PSM strategy and real-life execution, where valuable data and insights are lost, and important safety measures lack the impact required to drive change. It is difficult to keep track of the effectiveness of PSM initiatives on site; feedback to improve bowties and risk assessments is not tracked; and information is difficult to share across sites and even across companies.

The time has come to connect these dots

Wolters Kluwer Enablon has spent the last decade leading the development of Integrated Operational Risk Management, and provides staff across PSM, EHS and Operations with useful, outcome-focused solutions that transform the way companies work for the better. With Enablon, your bowties, risk assessments and incident data are no longer static. Your risk data is operationalized and visualized across three dimensions:

People: View past incidents related to equipment, location or hazards directly from Enablon’s permit to work system, empowering your staff to make better decisions based on real-time information. This includes near misses and barrier impairments, which can provide unique insights into improving safety measures or mitigation actions.

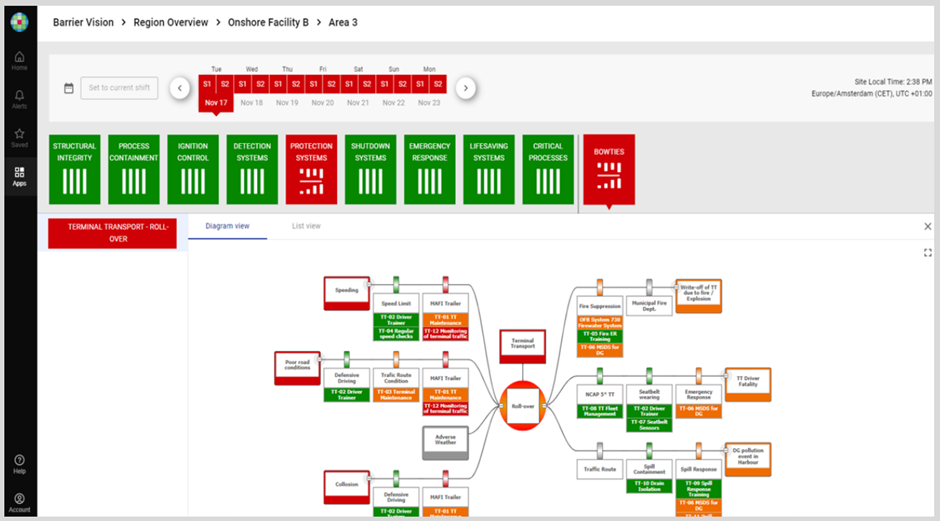

Process: Operationalize and visualize your bowties to improve front-line behavior without hassle, providing staff with one-click insights into the state of critical barriers in their work location – and automatically import incident and assurance information into your bowties to increase their quality.

Plant: View aggregated risk levels and various leading indicators on your site graphics based on real-time equipment information, barrier status, and SIMOPS.

Enablon’s deep-level integration empowers staff across domains to contribute to and operationalize critical safety and process knowledge.