Data for All: Bridging the IT-OT Divide for the Future of Digitalization

In today’s complex and ever-changing technological landscape, integration between Information Technology (IT) and Operational Technology (OT) is not just a buzzword; it’s a necessity. AspenTech Inmation is solely dedicated to eliminating the gap between IT and OT, providing our customers the solutions they need to successfully accelerate data-driven value creation in asset-intensive industries.

Versatility

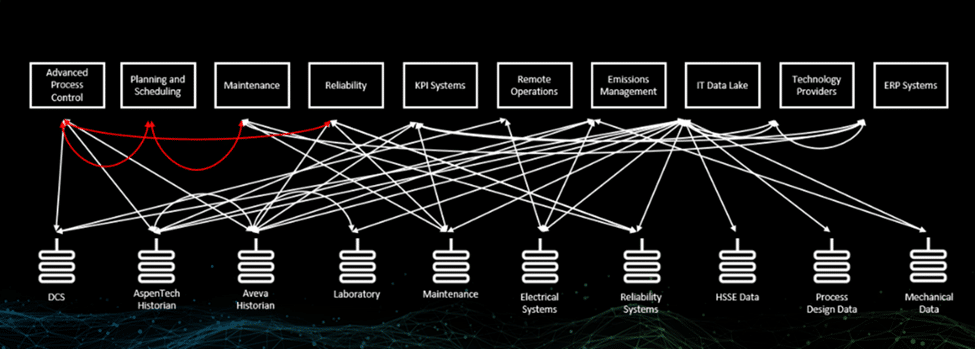

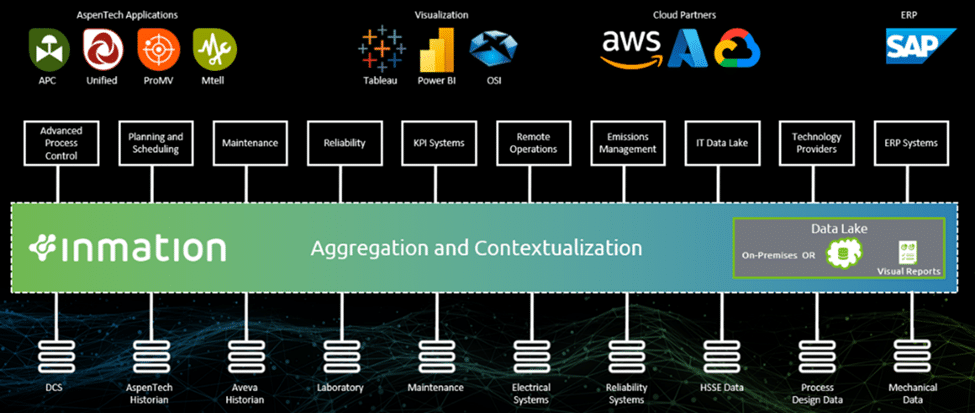

AspenTech Inmation offers a modular and systematic approach to integrating existing software, providing a path through the “data dilemma” and avoiding the OT/IT “spaghetti” environment.

Data Movement and Scalability

AspenTech Inmation can be thought of as the data broker, bus, or hub that permits universal movement of data. With onboard MongoDB and multiple connection options, it enables secure communication across network layers, bi-directional data movement and storage of multiple data types – including images, waveforms, alarms and events storage. Multiple stores on different levels of the overall system can be configured to segregate the data based on type and usage.

Digitalization is crucial to the success of companies in the future and this agnostic approach to data sources ensures site-to-cloud connectivity across multiple layers, a central component for digitalization to enhance modularity and simplify connections.

Connecting Data for Better Processes in Life Sciences

AspenTech Inmation’s ability to bring together multiple data sources within facilities creates a seamless and integrated environment. Whether it’s connectivity to PLCs or other databases, the bi-directional data flow facilitates real-time reporting and visualization. This robust connection simplifies access and ushers in a new era of microservices utilization, leading to a sustainable and future-proof system that can respond to organizational needs with agility and precision.

The pharmaceutical industry, for example, is revolutionized by AspenTech Inmation’s approach to managing real-time, unprocessed process data. Integrating data from clinical and R&D devices, how professionals interact with critical information is standardized. From improving experiments to reducing manual work, AspenTech Inmation provides a more clinical and user-friendly interface. The innovative alignment of data offers unprecedented opportunities for image AI analysis and centralizes information batch by batch, leading to significant advancements in the field.

Managing Uptime and Safety Compliance in Asset-Intensive Industries

Asset uptime is improved with an insightful approach to predictive maintenance. By building custom dashboards, AspenTech Inmation provides a holistic view of live and historical data to calculate health scores. This helps prioritize maintenance and predict potential failures. The integration of datapoints such as ERP, live sensor data, analytics and vibration data into one system offers a streamlined process that increases reliability and efficiency. Furthermore, the platform is changing the mining landscape by ensuring that high-maintenance assets are handled proactively rather than reactively.

Safety is paramount in industrial environments and AspenTech Inmation is at the forefront of enhancing safety protocols. By integrating process alarms, events and metadata, a comprehensive view of facility safety becomes available. This includes alarm management to prevent operator overload during disruptions and an in-depth analysis of various plant states to provide insight into operational improvements. This focus on safety not only ensures compliance but enhances facility effectiveness and contributes to the bottom line.

By creating functional testing and reporting environments, AspenTech Inmation ensures that all DOE requirements are met with precision. Whether it’s a PLC, HMI, or data reporting structure via LUA scripting, every aspect of the testing process is streamlined. By automating previously manual tasks, a new paradigm for testing and compliance, allowing for agility and consistency, is now available.

Bridging the gap between operations and maintenance teams creates a dynamic and interconnected workflow environment. By initiating work orders from various platforms and maintaining bi-directional connectivity, AspenTech Inmation ensures that all processes are intertwined and responsive. Whether it’s connectivity to a computerized maintenance management system (CMMS) or integration with a shift log system, the way is paved for enhanced collaboration and efficiency within organizations.

Centralizing Data and the Future of Bridging the IT-OT Divide

Recently, a leading energy provider’s centralization of thermal heat generation through AspenTech Inmation’s platform showed how integration from the field to the cloud is key. By monitoring all energy generation and consumption, AspenTech Inmation provides a cohesive and transparent view of the entire system. Real-time insights on the platform’s dashboards are comprehensive, including remote devices and centralized assets. This facilitates intelligent decision-making and proves how AspenTech Inmation can be a game-changer in energy management.

AspenTech Inmation is effectively addressing the pressing challenges faced by companies at the crossroads of IT and OT worlds. The platform’s versatility extends to diverse industries, from life sciences to asset-intensive industries like mining, offering scalable and integrated solutions that are truly transformative.

At its core, AspenTech Inmation’s modular approach is set to redefine industry standards by seamlessly connecting disparate data sources, thus bridging the IT-OT divide. This transformation isn’t confined to a single sector; it’s reimagining the technological landscape across the board, and the journey has only just begun.

Our upcoming webinar will delve into this topic in greater detail. Register today and be part of the conversation. We look forward to your participation!