Unlocking the Future of Sustainable Aviation Fuels: Axens’ Expertise in Next-Generation Feedstocks and Biofuel Production

By Jeff Caton and Yvon Bernard

Three Major Feedstocks for the Future of SAF

In collaboration with its partners, Axens has developed expertise in utilizing the next generation of feedstocks for the production of Sustainable Aviation Fuels (SAF) and electronic Sustainable Aviation Fuels (e-SAF). These feedstocks include biomasses, CO2, and hydrogen. For e-biofuels (use of biomass and additional low carbon / renewable hydrogen), the main feedstock is typically biomass, which encompasses residues from agriculture, forestry, and other waste products that do not compete with food crops. On the other hand, for e-SAF, the primary feedstock is CO2 (low carbon/biogenic), which can be captured from sources like flue gas, cement or steel factories, and power plants. In both cases, the feedstocks are combined with hydrogen to produce e-fuels or SAF.

Expertise in Biofuel Production:

The ASTM D7566 standard for aviation fuels permits various technological pathways for the synthesis of kerosene. Axens provides commercial solutions for a few of these pathways, including HEFA-SPK and ATJ-SPK, which are specifically designed for bio-based Sustainable Aviation Fuels (SAF), and FT-SPK, which can be utilized for both SAF and electronic SAF (e-SAF) production.

Expertise in Gasification of Biomass

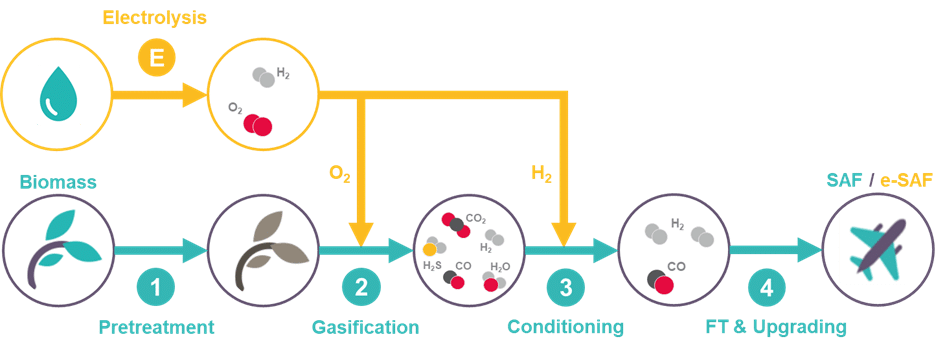

Under the FT-SPK pathway, the BioTfueL® (biomass-to-fuel) technology enables the combination of lignocellulosic biomass and renewable hydrogen to produce high-quality Sustainable Aviation Fuels (SAF). The biomass feedstocks used in this pathway are diverse and can include energy crops like miscanthus, agricultural waste such as bagasse, rice straw, and wheat straw, as well as forestry residues. This pathway is particularly suitable for farmers and industrial players who have access to large volumes of these natural residual products. The FT-SPK pathway involves the heating of biomass through torrefaction and converting it into a gas through gasification. Renewable hydrogen plays a crucial role in improving carbon efficiency during syngas conditioning. It is combined with syngas under appropriate conditions to create hydrocarbon products through Fischer-Tropsch synthesis

Combining biomass and renewable hydrogen can create valuable synergies. The same infrastructure and units are shared, and the biogenic carbon source is concentrated and cost-free.

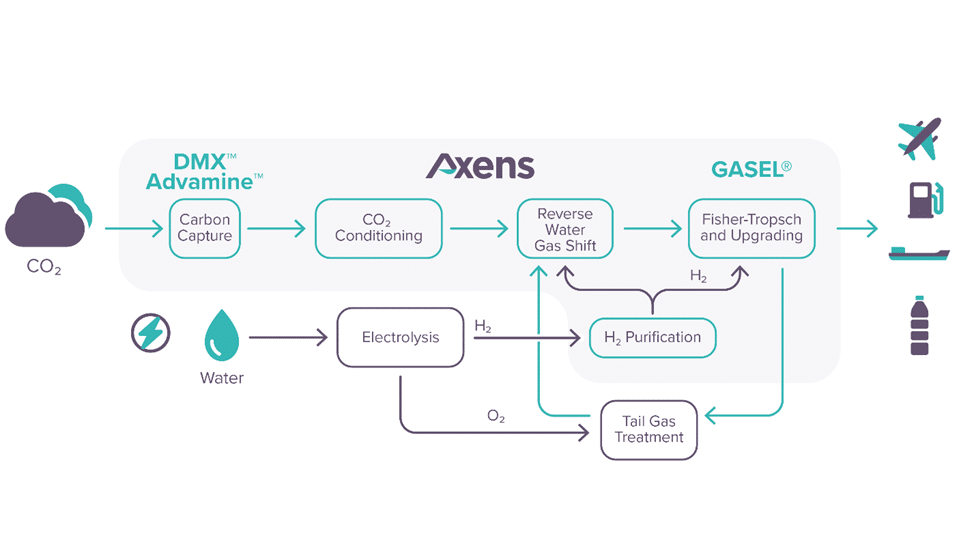

Expertise in e-fuel Production: The CO2 Pathway

The pathway for e-SAF production involves combining CO2 with renewable hydrogen. Axens offers a comprehensive e-SAF portfolio, which includes the RWGS technology, carbon capture solutions DMX™ and Advamine™, syngas catalysts, adsorbent materials, and its Fischer-Tropsch solution Gasel®.

Since renewable hydrogen is still expensive and CO2 resources are limited until direct capture technologies become more advanced, Axens has developed an integrated e-fuel complex that achieves near-complete carbon recovery and optimized hydrogen consumption. Maximizing resource utilization is a crucial requirement for the widespread adoption of e-SAF.

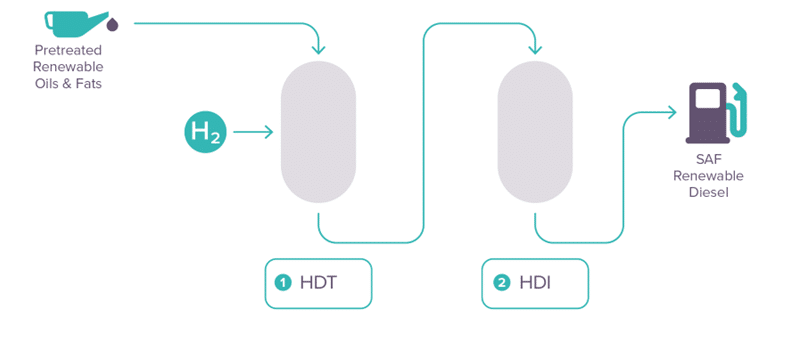

Expertise in Vegetable Oils and Animal Fats

Renewable vegetable oils and animal fats (lipids) can undergo hydrotreating to produce Hydroprocessed Esters and Fatty Acids (HEFA) suitable for use as renewable diesel and renewable kerosene for Sustainable Aviation Fuels (SAF). Over the past decade, numerous hydrotreating plants have been constructed, and there are currently 10 operating units (some in operation, some under construction, and some soon to start) that utilize the Vegan hydrotreating process licensed by Axens (refer to Figure 2). In this process, the lipids are hydrotreated to eliminate oxygen and other impurities, followed by a hydroisomerization step to enhance the quality of the linear paraffins. The Vegan technology can be easily adjusted to meet the required boiling range and cold flow properties of the desired product, allowing operators to optimize the production of renewable diesel and/or SAF based on market demand.

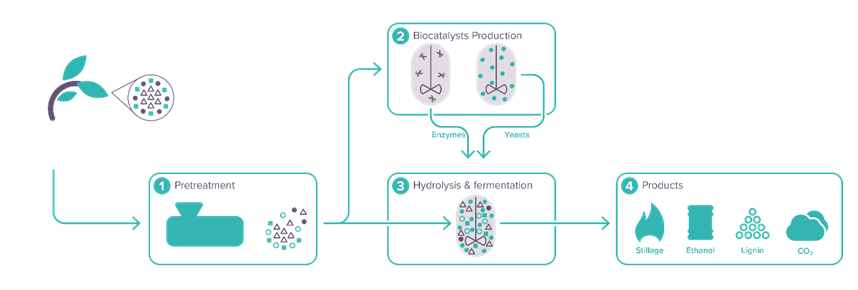

Expertise In Advanced Ethanol And Alcohol to Jet

Lignocellulosic biomass residues, such as wood chips, straw from cereal crops, bagasse, rice straw, and bamboo, can be converted into advanced ethanol (Futurol) through enzymatic fermentation. A further catalytic conversion to advanced biofuels is proposed via Alcohol to Jet (Jetanol) to produce SAF. Lignocellulosic biomass is composed of three major components: cellulose, hemicellulose, and lignin. Hemicellulose is then transformed into monomeric sugars. On-site production of enzymes and yeasts is implemented for economic reasons, eliminating the need for external supplies. The enzymes are utilized for enzymatic hydrolysis of cellulose into sugar monomers, while yeasts simultaneously ferment these sugars into ethanol. The fermented mash resulting from the hydrolysis and fermentation step is processed to separate and recover various products, including fuel-grade ethanol, lignin, clarified stillage, and CO2.

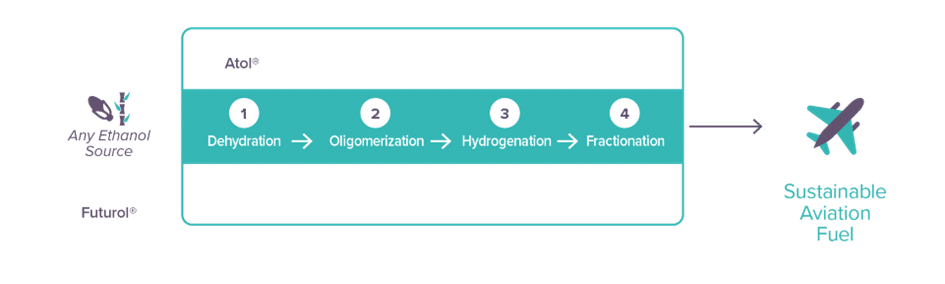

Catalytic conversion of advanced/bioethanol to ethylene through the energy-efficient Atol process offers a sustainable solution for the production of bio-ethylene, a key step in decarbonizing ethylene-based chemicals like plastics. The process involves dimerization to butenes and hexenes, followed by oligomerization to the kerosene range, ensuring compliance with ASTM D7566 specifications.

Conclusion

South East Asia’s abundant feedstock resources, such as palm residues like POME and Empty Fruit Bunch, offer diverse utilization opportunities. These include producing sustainable aviation fuels and renewable diesel for heavy trucks and maritime use, as well as naphtha for the petrochemical sector. These technologies have advanced beyond the demonstration phases, thanks to collaborations with experienced partners who excel at scaling up technologies.

Industries across the region now have the means to reduce their carbon footprint and explore various applications by repurposing existing assets and by-products. This not only allows for higher product margins but also aligns with the crucial goal of reducing greenhouse gas emissions.

Mr. Yvon Bernard

Business Development Manager, Renewables Product Line, Technology & Technical Support Business Division

Email: Yvon.BERNARD@axens.net