Unconventional Improvement of Propylene Recovery at the Propylene-Propane (PP) Splitter

By: Massimo Capra, Aggreko Process Services Manager

Introduction

In a Propylene-Propane (PP) Splitter, the top condensation temperature is set by the available cooling water temperature; in order to limit the condenser size the ΔT approach should be approx. 5-10°C. Consequently the top pressure of the PP Splitter will be very close to the resulting propylene vapor pressure at the corresponding condensation temperature which is typically around 20-23 barg.

In other words, the higher the temperature of the available cooling water, the higher the top pressure of the PP Splitter will be. When considering a condensation at 50°C, the propylene vapor pressure is 2071 kPaa, while the propane vapor pressure is 1720.4 kPaa, the resulting relative volatility is 1.2. The higher the operating pressure of the PP Splitter, the lower the relative volatility will be, resulting in lower separation efficiency and hence lower propylene yield.

Case Study: The Problem

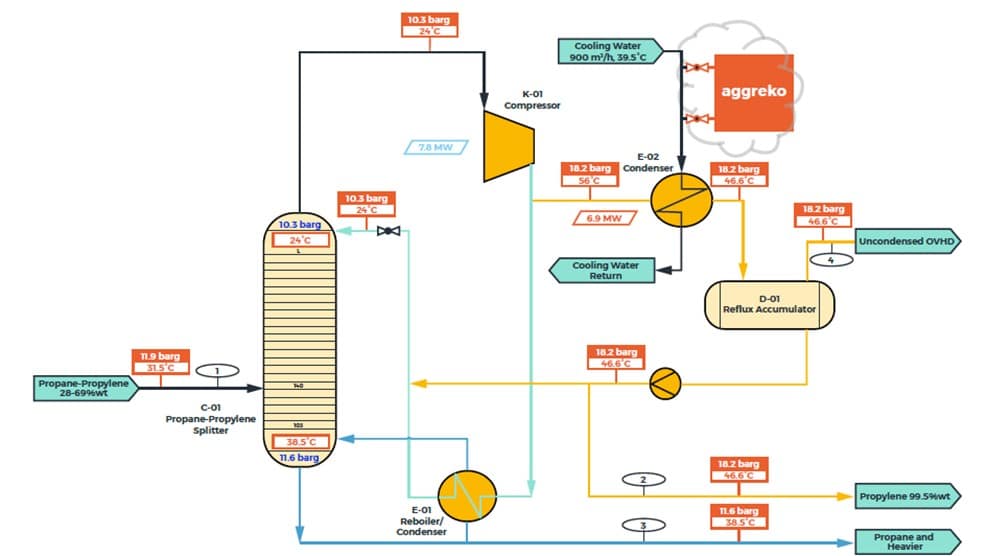

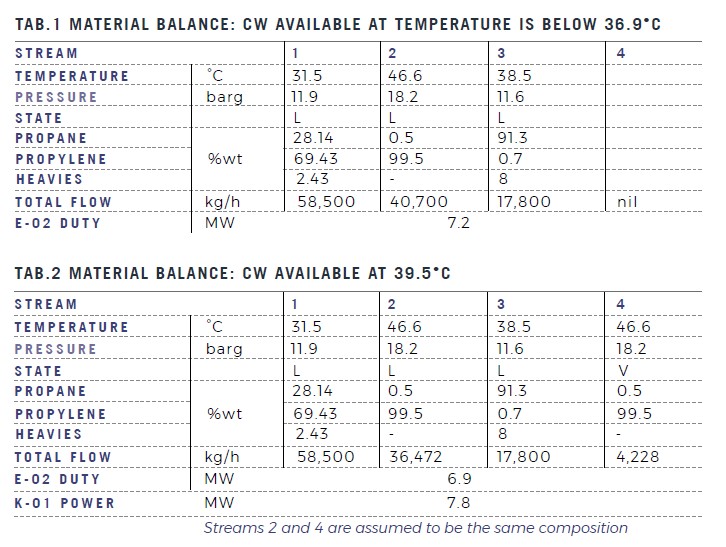

Modern PP-Splitters perform condensation-reboiling by thermocompression (Fig. 1). As the distillation is conducted at low pressure (8.3 barg) the gross overhead dew point is increased from 24°C to 46.6°C by increasing the pressure up to 18.2 barg. The column bottom is reboiled at 38.5°C and 11.6 barg; this allows the reboiling and condensing operations to be performed in a single heat exchanger utilising the condensing vapors as reboiling medium. As a rule of thumb, the water-cooled condenser approximately removes the equivalent thermal power introduced by the compressor, when total condensation is achieved.

The above PP splitter produces Polymer Grade Propylene (99.5%) out of Refinery Grade Propylene granting a recovery yield of 99.7% of the propylene feed when the cooling water temperature at the condenser E-02 is lower than 36.9°C. At higher water temperature, vapors are vented from the Reflux Accumulator D-01 (see Tab. 1&2 for material balance).

Historical records showed cooling water temperature supplied at E-02 was as high as 39.5°C in summer daytime with recovery yield dropping down to 60%. This forced the operator to reduce the PP Splitter capacity; otherwise at 910 Euro/ton (trading price of propylene at project time), losing 4,228 kg/h of PGP meant flaring 3,800 Euro/h for at least 7 hours/day. This equates to a loss of 2.7 million Euros over a 100-day period.

Case Study: Aggreko’s Solution

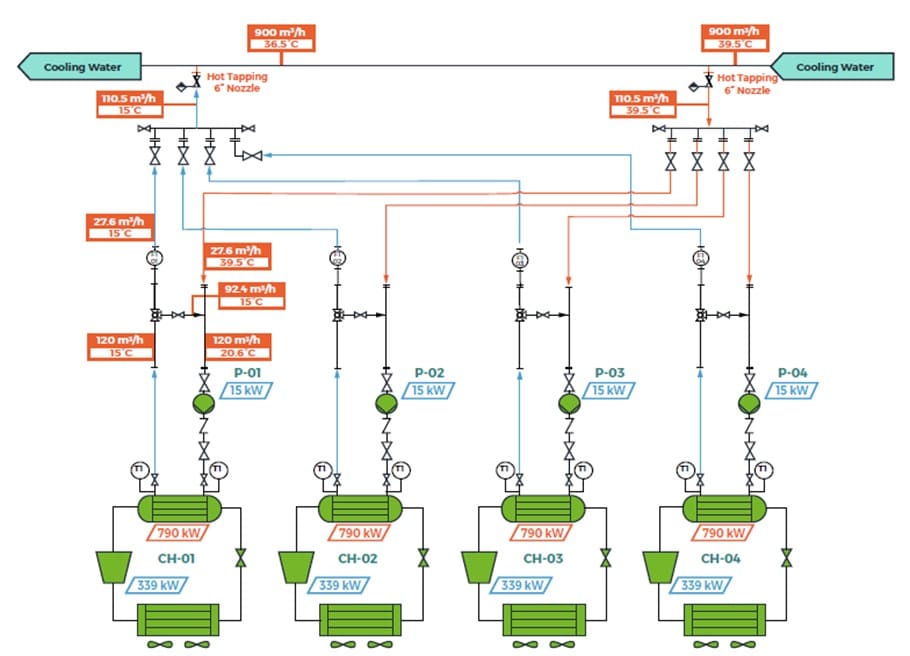

Cooling 900 m3/h of water from 39.5°C to 36.5°C engaged a maximum 3,160 kW of refrigeration capacity, which must be tuned (reduced) during night hours in order to grant stable operations of the PP-Splitter.

The cooling water feed line to E-02 had to be modified for extraction of 110.5 m3/h of water at max temperature of 39.5°C (see Fig.2), refrigerated in four mobile air-cooled chillers in parallel at 15°C and reinjected in the feed line to be mixed with the remaining cooling water and produce a stream at 36.5°C. Mechanical modifications consisted of two 6” valved nozzles.

Chillers set point was fixed at 15°C at all time, while the 3-way-valves equipping each chiller provided control of the drawn cooling water flow rate in order to keep the final cooling water stream at a constant temperature of 36.5°C (day and night).

As the maximum refrigeration delivered by four chillers was 3,216 kW and the solution was modularly configured, the option to add a fifth chiller to increase cooling capacity was maintained.

To avoid any modifications of the refinery electrical installation, the solution was powered by two mobile diesel generators (1,250 kVA) and a fuel tank with remote monitoring which allowed diesel to always be supplied on time. All working parameters (mainly drawn water flow rate, inlet/outlet temperatures and final cooling water temperature) and motor status were constantly recorded and remotely monitored. The implemented solution was fully automated and process-wise intrinsically safe such that it did not require any operator presence.

Conclusion

Propylene recovery yield was improved significantly with the increase in condensation capacity during the most critical hours of the day; PGP was on spec at all times.

The solution (see Fig.2)was engineered by Aggreko Process Services, mobilised, commissioned and started up in 8 weeks with no CAPEX involved, since it was a Leased Engineered Temporary Solution, which is an unconventional approach to temporary process enhancement.

This new approach opens the way to a new class of projects which allows customers to harvest time-limited market opportunities or mitigate utilities upsets on an as-need basis.