Exploring RTI’s Heat Exchanger Management Programme

A Complete Program for Heat Transfer Efficiency

The Challenge

Refined Technologies found that refiners typically sub‐optimize their heat transfer systems for several reasons:

- The problem of heat exchanger fouling is often set aside for other process concerns.

The Solution

To address these common constraints, RTI developed the Heat Exchanger Management (HXM) program. HXM, a comprehensive heat exchanger management program powered by our proprietary HeatTrax™ technology, is used to manage pre-heat performance and restore duty to fouled heat exchangers. Best coupled with our in-situ cleaning technologies and innovative ultrasonic mechanical cleaning services during normal crude unit operations, HXM provides powerful insights into operations.

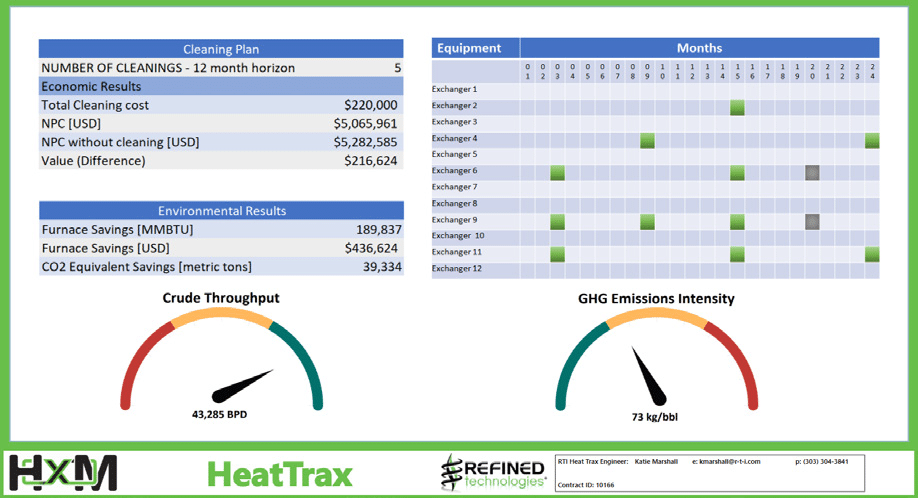

The goal of the HXM program is to optimize crude unit throughput by implementing proactive exchanger cleanings and to maintain preheat efficiency over time. All cleaning decisions produced from the HeatTrax™ scheduling optimizer are backed by economics. By taking into account crude margin and LPO, cleaning costs, fuel gas costs, and carbon costs (when appropriate), HeatTrax™ enables sites to move forward with actionable items and the economic justification to execute the recommended work.

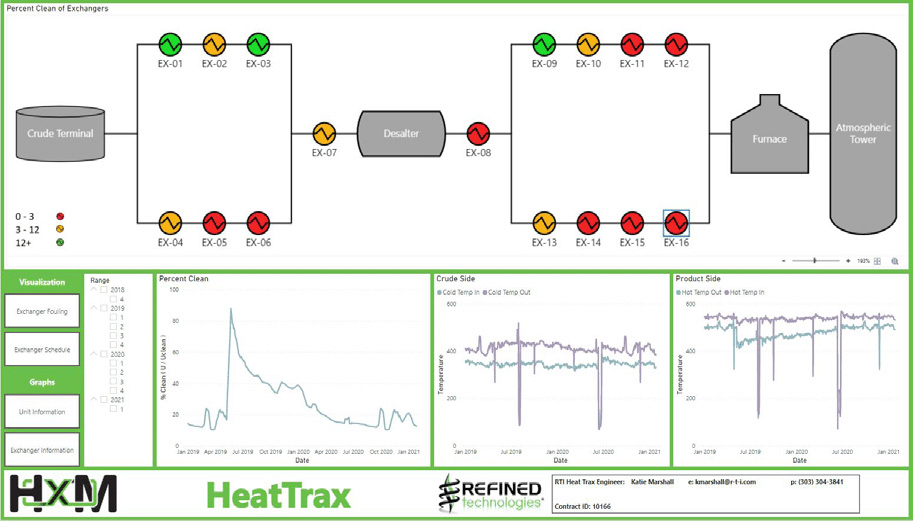

Through years of experience, RTI found maximizing preheat efficiency and furnace inlet temperatures are a result of two deliberate strategies: engineered monitoring and strategic cleaning. HeatTrax™ uniquely combines both strategies into a comprehensive program designed to maintain a targeted furnace inlet temperature range for clients. As a part of the managed Heat Exchanger Management program (HXM), CruzAlta engineers will monitor client’s preheat network, run the HeatTrax™ scheduler, and maintain the software.

The Application

CruzAlta thoroughly analyzes the preheat network looking for answers to several questions. Typical questions include which bundles should be cleaned, when should they be cleaned (frequency), and how should they be cleaned. CruzAlta engineers also have the ability to run various sensitivities and what-if scenarios, evaluating all options for clients. Upon completion of the assessment, data summaries, analysis reports, and a recommended cleaning schedule are provided.

Monitoring is necessary, and by itself will not improve heat transfer performance. When combining rigorous monitoring with strategic cleaning, real performance objectives are measured and met. A complete heat exchanger network cleaning program must meet three requirements.

The program must:

- Meet the heat transfer improvement objectives.

- Be economically or environmentally justified.

- Be executable.

Economic Benefits

Through our initial implementations of the HXM program at other sites in the U.S., facilities are seeing improvements in the following areas:

- Reduction in maintenance costs by implementing proactive in-situ cleaning, instead of mechanical pull and clean options.

- Reduction in fuel gas costs, due to improved exchanger efficiency.

- Associated reduction in GHG emissions (and potential reduction in carbon credits).

- Improvements to throughput for units running up against heater constraints.

Traditional hydroblasting restores heat transfer, but at a cost. Hydroblasting requires extensive manpower and can cause significant out‐of‐service time. Although RTI’s solution requires significant mechanical setup, liquid circulation with RTI’s UpperCut® chemistry is faster than hydroblasting and more effective than vapor-phase cleaning on heavily fouled equipment. RTI’s patented Vaporganic process can be completed in less than one shift and only requires manpower to isolate and drain the exchanger. For this process, RTI utilizes the most powerful, proven organic solvent used in chemical cleaning, Super Q®.

In the refining industry, RTI is the only provider that can uniquely deliver the engineering services necessary to monitor preheat trains AND the required technology to keep the train running at optimum conditions. HeatTrax™ is a lump‐sum, annual program that achieves specific furnace inlet temperature results, eliminating incremental costs for cleaning or monitoring.