PETRONAS Head of Process Safety says PSM key to operations

When it comes to process safety, it is imperative that front-liners are able to identify hazards and risks in their daily tasks, says Sufyan Nor, Head of Process Safety Management at PETRONAS.

“Managers, supervisors and specialists need to provide effective support to the front-liners in a timely manner… The leadership team then needs to be able to bring everything together to achieve flawless operations.”, he says.

Sufyan’s day-to-day operations and responsibilities include overseeing the implementation of process safety across the company’s downstream businesses, as well as contributing to the overall leadership and direction of process safety within the organisation.

“These days, they’re full of online meetings!” he laughs.

Process safety management (PSM) involves the identification and management of risks and hazards throughout the facility’s life cycle, from design and fabrication to construction, as well as the operating and decommissioning phases.

“Over the years, we have seen significant improvement in the awareness and understanding of PSM,” says Sufyan. “At PETRONAS, we are now moving into a maturity stage where a wholistic view of process safety is appreciated even more by a broader section of the workforce.”

Of course, he elaborates, this hasn’t always been the easiest task.

“To sustain this as a culture in the workplace, visible leadership commitment is required to maintain discipline and ensure continuous improvement. Like many classic process safety incidents, we have observed gaps appearing over time and at different stages of the facility life cycle, which impacted our operations.”

But the challenges remain, even if they seem fairly straightforward. Firstly, attracting the right people for the job can be difficult, especially since they need to have operational knowledge across technical and non-technical subjects.

The second challenge can prove to be trickier and falls largely on leaders to create an environment where workers can feel safe in addressing or escalating early warning signals, whenever necessary. “People should feel safe in raising concerns,” stresses Sufyan. “Leaders should not only welcome these concerns, but also show genuine interest in pro-actively identifying challenges so that they can be dealt with in a timely manner.”

How do operators ensure that PSM is properly implemented across all workers, though? According to Sufyan, making sure people understand the big picture is key. In making sure workers understand how important PSM and its risk controls are in their daily work, leaders can highlight the importance of competent and effective task execution.

Think of it like a vaccine, he says. “Workers need to be periodically ‘injected’ with healthy doses of chronic unease through the effective sharing of gasps, near-misses and incidents. Regular engagements – which should not be restricted to formal meetings or events – will help strengthen the message to the workforce on the importance of PSM.”

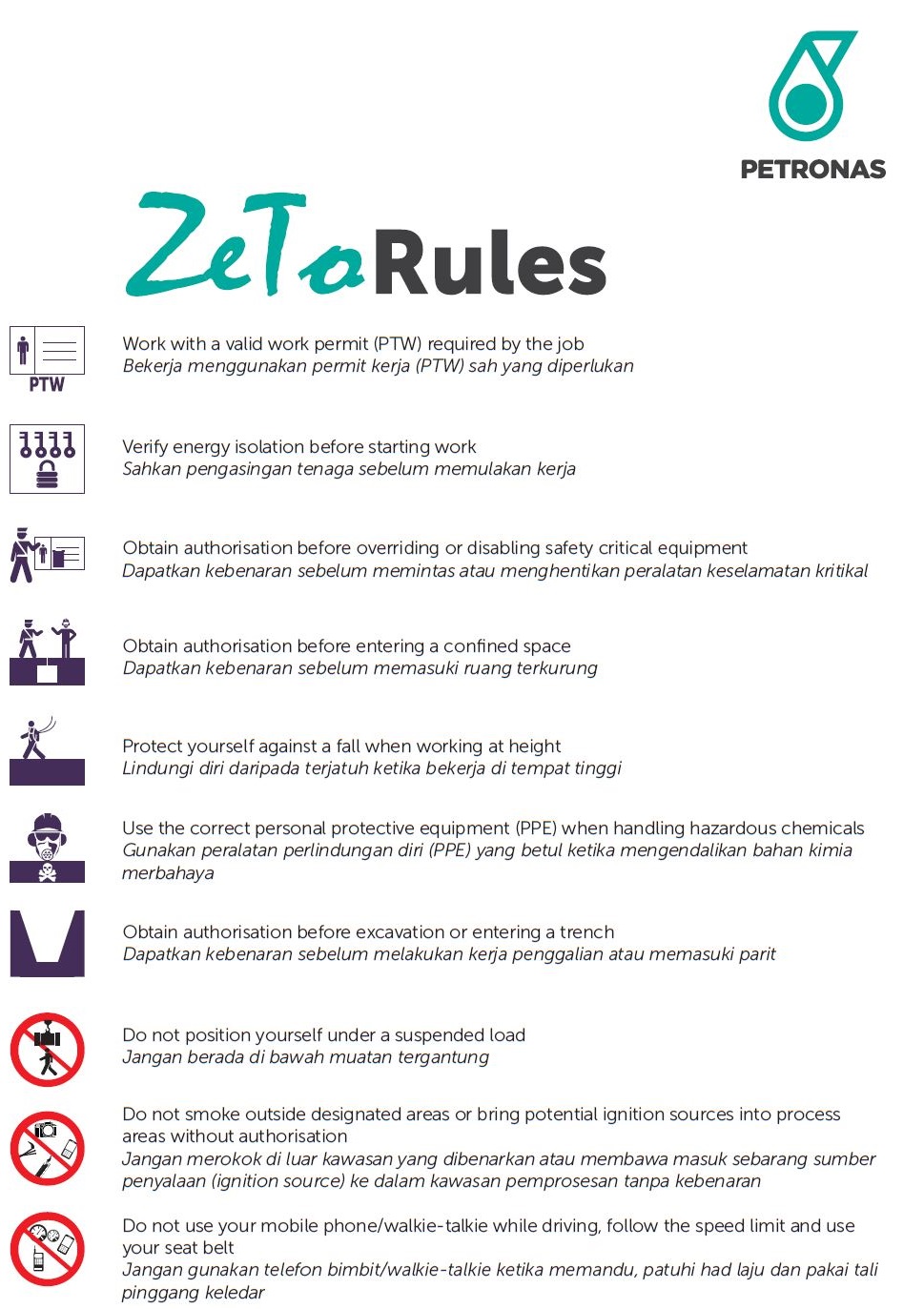

Setting a firm example in this regard is PETRONAS, with zero-tolerance rules in place for workers to follow. Also known as “ZeTo Rules”, these prescribe 10 mandatory principles which must be adhered to by everyone, including third-party personnel, at PETRONAS facilities. Recently, PETRONAS has also introduced PSM-related behaviours into the workplace with a Process Safety Essentials campaign, and Process Safety Golden Rules that serve as reminders for front-liners.

However, PSM as we know it today will evolve and change with the times, thanks to factors like digitalisation and increased system integration. In time, Sufyan says, relevant operating and technical data, as well as analytics, will likely be available on a single platform as a single source of truth, on a near real-time basis.

Slowly but surely, PSM will grow to be a culture that is embraced by the entire organisation.